Get instant machine shop quotes online for custom parts. CNC machining service with fast quotes and free CAD. Try our cost calculator now!

Machine Shop Quotes online Services (Cost Calculator & Online Quotes)

Instant Quotes

Instant Quotes

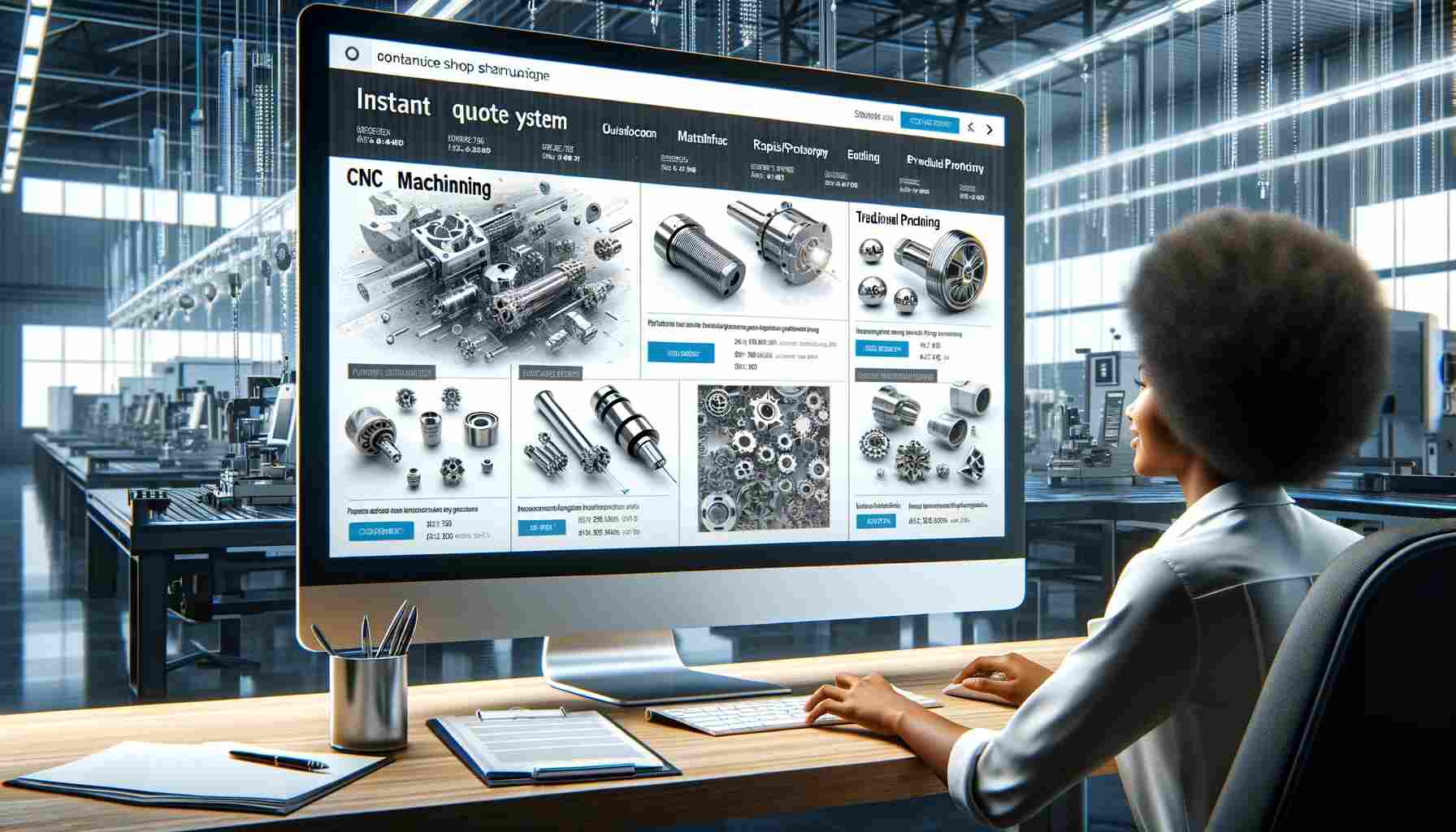

Machine shop quotes online services provide instant quotes for machined parts, allowing customers to quickly and easily obtain pricing information for their custom manufacturing needs.

By simply inputting the specifications of the required parts, such as material type, dimensions, and quantity, customers can receive immediate cost estimates. This streamlined process saves time and enables businesses to make informed decisions about their production requirements without delay.

- The convenience of obtaining instant quotes also allows for better planning and budgeting within manufacturing projects.

- For example, a company in need of precision components can swiftly assess the costs involved in producing these parts through an online machine shop service.

- This quick access to pricing information empowers businesses to efficiently manage their resources and ensure that they stay within budget constraints.

CNC Machines

In traditional machining methods utilized by machine shops, including those offering online quoting services, CNC machines play a pivotal role in fabricating metal parts with high precision. These advanced computer-controlled machines enable intricate designs and complex geometries to be accurately replicated from digital models into physical components. The utilization of CNC technology ensures that custom parts are manufactured with exceptional accuracy, meeting the exact specifications outlined by customers.

- Moreover, CNC machining offers unparalleled efficiency in producing large quantities of identical components while maintaining consistency across each piece.

- As a result, machine shop quotes online services leverage the capabilities of CNC machines to deliver cost-effective solutions for mass production requirements without compromising on quality or precision.

Online Machine Shop Instant Quote

Online Machine Shop Instant Quote

Wide Range of Manufacturing Processes

Machine shops offering online instant quotes provide a wide range of manufacturing processes. These include CNC machining, traditional machining, rapid prototyping, and production parts. Customers can easily access information about the different processes available for their specific needs.

For instance, if a customer requires precision parts with complex geometries, they can explore the CNC machining options offered by various machine shops online. This allows them to understand the capabilities and limitations of each process before requesting a quote.

- Moreover, these online platforms often detail the types of materials that can be used for fabrication as well as any specific tooling options available.

- This level of transparency empowers customers to make informed decisions based on their project requirements.

Tooling Options for Custom Parts

When obtaining an instant quote from an online machine shop, customers have access to various tooling options suitable for custom parts. Whether it’s cutting tools or milling equipment needed for a specific job, individuals can view the available resources provided by different service providers.

- For example, a customer seeking quotes for large-scale production parts may require specialized tooling to ensure efficiency and accuracy in manufacturing.

- By having visibility into the tooling options offered by different machine shops online, customers can assess which provider aligns best with their production needs.

Instant Online Quoting for Machined Parts

Instant Online Quoting for Machined Parts

Rapid Prototyping and Production Parts

Obtaining machine shop quotes online streamlines the process of acquiring rapid prototypes and production parts. This method expedites the manufacturing process, allowing for quicker turnaround times. For example, a company needing custom metal parts can swiftly obtain quotes for CNC machining services, enabling them to proceed with production promptly.

- The instant quoting system facilitates efficient decision-making by providing cost estimates in real-time.

- This allows businesses to evaluate different manufacturing processes and materials quickly, helping them make informed choices based on their budget and timeline.

- As a result, companies can accelerate their product development cycle without delays caused by waiting for traditional quotations.

Traditional Machining vs. Instant Quotes

Comparing traditional machining methods with instant quotes reveals significant advantages in terms of time-saving and convenience. Unlike the conventional approach that involves back-and-forth communication with machine shops to obtain quotations, the online quoting system delivers immediate pricing information at any time of day or night.

Consequently, this modernized process eliminates unnecessary delays associated with manual quote generation.

- Moreover, leveraging an instant quoting platform reduces errors commonly found in manual quotations due to human factors or miscommunication during the negotiation phase.

- By receiving accurate quotations instantly through digital platforms, companies can mitigate potential misunderstandings regarding project requirements and costs.

Reducing Turnaround Time for Machined Part Quotations

Rapid Prototyping

Rapid prototyping and instant quote tools have revolutionized the process of obtaining machine shop quotes online. These tools allow manufacturers to quickly upload their design files, select materials and quantities, and receive instant quotations. For example, a manufacturer needing custom parts can simply upload their CAD file to an online platform, specify the required material and quantity, and instantly receive a quote. This significantly reduces the time spent on back-and-forth communication between the manufacturer and the machine shop.

- Advanced manufacturing processes such as CNC machining enable rapid prototyping by swiftly translating digital designs into physical parts.

- CNC machines precisely fabricate components with tight tolerances, ensuring high accuracy in the final product.

- The combination of rapid prototyping tools and CNC machining has drastically reduced lead times for machined part quotations.

Efficient tooling is also crucial in expediting quotation turnaround time.

- Machine shops equipped with advanced cutting tools can streamline production workflows, resulting in faster processing of quotation requests.

- By optimizing tooling strategies, machine shops can ensure quick setup times for producing prototype or production parts.

Streamlined Production Workflows

Streamlined production workflows play a pivotal role in reducing lead times for machined part quotations through efficient resource allocation and optimized scheduling. By leveraging modern technologies such as automated scheduling software, machine shops can effectively manage orders, prioritize urgent requests, and allocate resources judiciously to minimize downtime.

QuickTurn Machining: Custom, Quality, Fast Service

QuickTurn Machining: Custom, Quality, Fast Service

Quick and Custom Machined Parts

QuickTurn Machining specializes in providing custom machined parts with tight tolerances. This means that customers can get precisely tailored components that meet their specific requirements, ensuring a high level of accuracy and performance. With the ability to produce custom parts, clients have the flexibility to obtain unique solutions for their projects, whether it’s for prototyping or full-scale production.

- The online quoting system allows customers to input their specifications and receive an instant quote for their desired parts.

- This streamlines the process significantly compared to traditional methods where obtaining quotes may take much longer due to manual calculations and communication delays.

Rapid Prototyping and Manufacturing Processes

QuickTurn Machining is dedicated to offering fast service for both rapid prototyping as well as regular manufacturing processes. By leveraging advanced CNC machines, they can efficiently produce prototypes or final products within a short lead time.

This capability is especially beneficial when there’s a need for quick iterations or urgent production runs.

Customers no longer have to wait extended periods before receiving quotes or waiting weeks for their custom parts since everything can be swiftly processed online with reduced lead times.

Fast and Affordable CNC Machining Solutions

Fast and Affordable CNC Machining Solutions

Instant Quoting Process

When customers require custom parts promptly, obtaining a quote online is crucial. The convenience of receiving instant quotes for both rapid prototyping and production runs enables clients to make informed decisions swiftly. This seamless process allows for efficient planning and budgeting, ensuring that projects stay on track.

- The ability to obtain quick CNC machining quotes online empowers businesses to streamline their operations by eliminating the need for lengthy negotiations or waiting periods.

- By leveraging this service, companies can expedite the development of prototypes or move into full-scale production more rapidly than ever before.

Extensive Range of Services

Online platforms offering machine shop services provide an extensive range of capabilities, including traditional machining and milling processes. These services cater to a wide variety of industries and applications, allowing businesses to fulfill their specific manufacturing needs efficiently.

Benefits of Instant Online CNC Machine Shop Quotes

Benefits of Instant Online CNC Machine Shop Quotes

Quick and Accurate Cost Estimates

Instant online CNC machine shop quotes offer swift and precise cost estimates for custom parts. By inputting the specifications, customers can swiftly obtain accurate pricing information without delays.

This is particularly advantageous when compared to traditional machining methods, which often involve extensive back-and-forth communication with a machinist before receiving a final quote. With instant online quotes, individuals can promptly assess the feasibility and cost-effectiveness of their projects.

- Moreover, this streamlined process reduces the potential for errors in manual calculations or miscommunications that could occur during the traditional quotation process.

Exploring CNC Turning and Milling

Advanced Machining Processes

CNC turning and milling are manufacturing processes that utilize computer-controlled machines to shape and cut metal parts with precision. These advanced machining methods have revolutionized the production of machined parts, offering unparalleled accuracy and efficiency. Traditional machining techniques are being rapidly replaced by these modern approaches due to their numerous advantages.

- CNC machines have transformed the manufacturing industry, providing faster production times and exceptional precision in creating complex parts.

- By using numerical control, CNC turning and milling ensure that tight tolerances can be achieved consistently, making them ideal for rapid prototyping and fabrication of intricate components.

Benefits Over Traditional Methods

Compared to traditional machining, CNC turning and milling offer several distinct benefits. These include quicker turnaround times, enhanced accuracy in producing machined parts, reduced manual labor requirements, minimized material waste, improved repeatability, and increased overall productivity. The use of cutting-edge technology also allows for more efficient tooling utilization during the manufacturing process.

- Faster production times

- Higher accuracy in creating complex parts

- Ideal for rapid prototyping

- Consistent achievement of tight tolerances

Custom CNC Milling and Metal Fabrication Services

Benefits of Online Machine Shop Services

Online machine shop services offer numerous advantages, including quick access to custom parts and cost-effective solutions. By leveraging the power of the internet, customers can easily request quotes for their specific machining needs without the need for in-person visits or lengthy negotiations. This streamlined process saves time and allows for efficient comparison of multiple quotes from different providers.

- With online platforms, individuals seeking metal fabrication or CNC milling services can enjoy the convenience of obtaining rapid prototyping at their fingertips.

- They can upload design files directly to the website, specify material requirements, quantities needed, and desired delivery times.

- This level of customization and accessibility significantly accelerates the production timeline while ensuring that precise specifications are met.

Considerations When Seeking Online Quotes

While acquiring machine shop quotes online presents several benefits, it’s essential to consider a few factors before making a decision. Customers should evaluate the provider’s capabilities in meeting tight tolerances, especially when dealing with intricate designs or complex geometries.

- Understanding whether a particular service offers traditional machining alongside CNC capabilities is crucial for projects requiring diverse manufacturing processes.

- Furthermore, individuals should assess if the online platform provides comprehensive information about available materials and finishing options such as anodizing or powder coating.

Transparency regarding these aspects helps clients make informed decisions based on their specific project requirements.

Instant Quotes

Instant Quotes Online Machine Shop Instant Quote

Online Machine Shop Instant Quote Instant Online Quoting for Machined Parts

Instant Online Quoting for Machined Parts QuickTurn Machining: Custom, Quality, Fast Service

QuickTurn Machining: Custom, Quality, Fast Service Fast and Affordable CNC Machining Solutions

Fast and Affordable CNC Machining Solutions Benefits of Instant Online CNC Machine Shop Quotes

Benefits of Instant Online CNC Machine Shop Quotes